The temperatures of the flue gases are usually less than 200 °C during this part of the process. Install thermal insulation to prevent the interior walls from cooling below the point where the acid contained in the flue gas condenses and forms corrosive deposits. Insulate the support structures in particular well to prevent cold bridges.

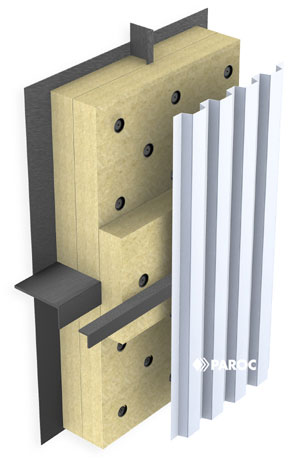

You can insulate critical areas, such as wall bracing structures, adhesive surfaces and access covers, effectively using multilayer insulation solutions with overlapping seams to make the insulation tight enough. Usually, slabs are used for both layers, but it is possible to combine slabs with wired mats.

|

|

For equipment and filters, Paroc recommends the following solution:

- Use a double layer insulation solution with 80 kg/m3 PAROC Pro Slabs.

- Fix the insulation with welded pins.

PAROC Pro Slabs provide excellent thermal insulation in the temperature range of flue gasses, have low air permeability, are moisture resistant and PAROC Pro Roof Slabs offer good compression strength in roof constructions.

|