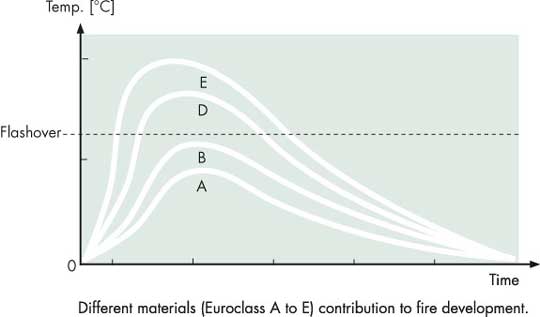

The reaction to fire classification describes how the product, as placed on market, contributes to fire development in the early phase of a fire. This is called Euroclass, which shall be determined in accordance with EN 13501-1. A material with a good Euroclass delays flashover as long as possible. After that, it is the fire resistance of a structure that is important (e.g. EI classification).

Reaction to fire is described with Euroclass A-F, with the addition of how much smoke (s1-s3) and flaming droplets (d0-d2) the product creates when exposed to fire.

| |

Contribution to fire

A - B - C - D - E - F |

Smoke intensity

s1 - s2 - s3 |

Burning droplets

d0 - d1 - d2 |

| A1 |

Flashover not possible |

No test needed |

No test needed |

| A2 |

Flashover not possible |

s1 = No or very little smoke

s2 = Limited amount of smoke

s3 = Much smoke |

d0 = No burning droplets

d1 = Droplets burn for less than 10 sec

d2 = No demand |

| B |

Flashover not possible |

| C |

Flashover after more than 10 minutes |

| D |

Flashover between 2 and 10 minutes |

| E |

Flashover in less than 2 minutes |

Not tested |

- or d2 |

| F |

Not tested |

Not tested |

Not tested |

Examples of Euroclass

* A2-s1, d0 (Flashover not possible, no or very little smoke, no burning droplets)

* B-s3, d1 (Flashover not possible, much smoke, droplets burn for less than 10 seconds)

For pipes the same Euroclasses are used, but with the subscript index “L” (e.g. A2L-s1, d0).

PAROC stone wool is Euroclass A1 and does not contribute to the development of a fire. The requirement varies depending on national regulations and those vary between European countries. PAROC stone wool reaction to fire does not change over time and gives the same top level, maintenance-free fire safety during the entire lifetime of the installations.

The Euroclass of the product is not shown in the designation code, but shall always be shown on the EC Declaration of Conformity and other product related information (e.g. datasheets and on the product label).