You can estimate the thickness of protection needed in a wide range of situations with methods that assess the performance of fire protection materials. The procedure is in two parts. First, carry out a carefully designed programme of fire tests on both loaded and unloaded specimens. Second, apply a mathematical procedure to the results of the tests, which enables you to predict the required thickness. These tests determine both the insulation characteristics of a fire protection material and its physical performance under fire conditions for a range of steel sizes. They generate the maximum amount of data from a minimum number of tests. (ENV13381-4)

Using fire design codes such as the Structural Eurocodes, EC3–1.2 and EC4-1.2, (designated EN 1993-1.2 and 1994-1.2), you can calculate the load on the structure at the time of the fire by treating it as an accidental limit state. This allows you to specify to the protection contractor a limiting or failure temperature for a given structural section.

The protection contractor will then be able to use the required thickness of material to ensure that the steel section does not exceed this temperature within the fire resistance period. Simplify this process by specifying a maximum steel temperature, based on the worst case, for all beams or columns on one floor level.

Thicknesses are given for a range of steel temperatures. It is the responsibility of the design engineer, using design codes such as ENV1993-1-2, to specify the appropriate limiting steel temperatures.

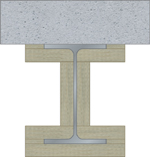

Steel columns and beams

Determine the rate of increase in the temperature of a steel cross-section using the ratio of the heated surface area (A) to the volume (V). This ratio, A/V, has units of m-1 and is known as the section factor. Elements with low section factors will heat up more slowly.

The images below present formulas for different profiles and their positions in the building.

A = 2a + 2b

|

A = 2b + 2h

|

A = b + 2h

|

A = 4b + 2h

|

A = 3b + 2h

|

|

|

|

|

|

A steel section with a large surface area (A) (m²/m) will receive more heat than one with a smaller surface area. Also, the greater the volume (V) (m³/m) of the section, the greater is the heat sink. It follows therefore, that a small thick section will be slower to increase in temperature than a large thin one.

The section factor (A/V) is thus a measure of the rate at which a section will heat up in a fire. The higher its value is, the more protection thickness is required. In calculating the section factor values, the full volume, V, is used whether the section is exposed on three or four sides, because the entire steel section will receive heat. A, however, is the exposed surface area and that depends on the configuration of the fire protection